Into the Twilight Zone

Back to updates- We have completed our initial tests with System 001/B

- A consistent speed through the plastic has been achieved using the parachute anchor configuration, therefore, solving our main technical challenge with Wilson

- However, the technology is not proven yet, as overtopping needs to be addressed before the plastic is effectively retained in the system

The Ocean Cleanup’s mission is to rid the world’s oceans of plastic. Our starting point for this is the Great Pacific Garbage Patch; the largest accumulation zone of plastic in the world. Doing so is tricky because 1) even though the patch contains north of 80 million kg of plastic, it is spread out over a massive area, three times the size of France or twice the size of Texas, and 2) the patch is remote (the center is five times further away from land than the altitude of the International Space Station), making vessels extremely expensive to run.

The solution, therefore, requires us to 1) concentrate the plastic before harvesting, and 2) limit vessel use by designing the cleanup systems to operate autonomously for long stretches of time. Compare the function of the cleanup system to a rake in a large lawn full of leaves. To clear the lawn, one could pick up the leaves one by one, which would take forever, or one could use a rake to concentrate the leaves into one big pile, to then pick up the pile in one go. This is the main principle behind our cleanup concept; yet, our “rakes” need to be able to survive for years in one of the harshest environment on this planet, while being able to hold on to the concentrated plastic without human aid.

THE IMPORTANCE OF TESTING

The journey to clean oceans can be roughly divided into three big steps:

- Prove the concept: by means of testing and iterating until we reach a design that can effectively collect and retain plastic for an extended duration

- Make the technology scalable: once the first system works, we optimize the design for cost and scalability

- Commence scale-up: Build up to a fleet of systems in the patch capable of cleaning at a rate of at least 50% of the patch every five years

As the problem is getting worse by the day, and as the plastic in the patch continues to fragment into toxic microplastics, it is therefore key that we reach proven technology status as soon as possible.

Our first attempt at doing so was deployed last year: System 001, also known as Wilson. After months of testing, we took Wilson back to port in the first days of this year after it suffered a fatigue fracture. This was not ideal, but both the diagnosis and solution came quite easily. The more complicated challenge was the system’s inability to retain plastic; instead of consistently going faster than the plastic, it alternated between going faster and going slower than the plastic. This meant plastic would float into the system, as planned, but then float out again.

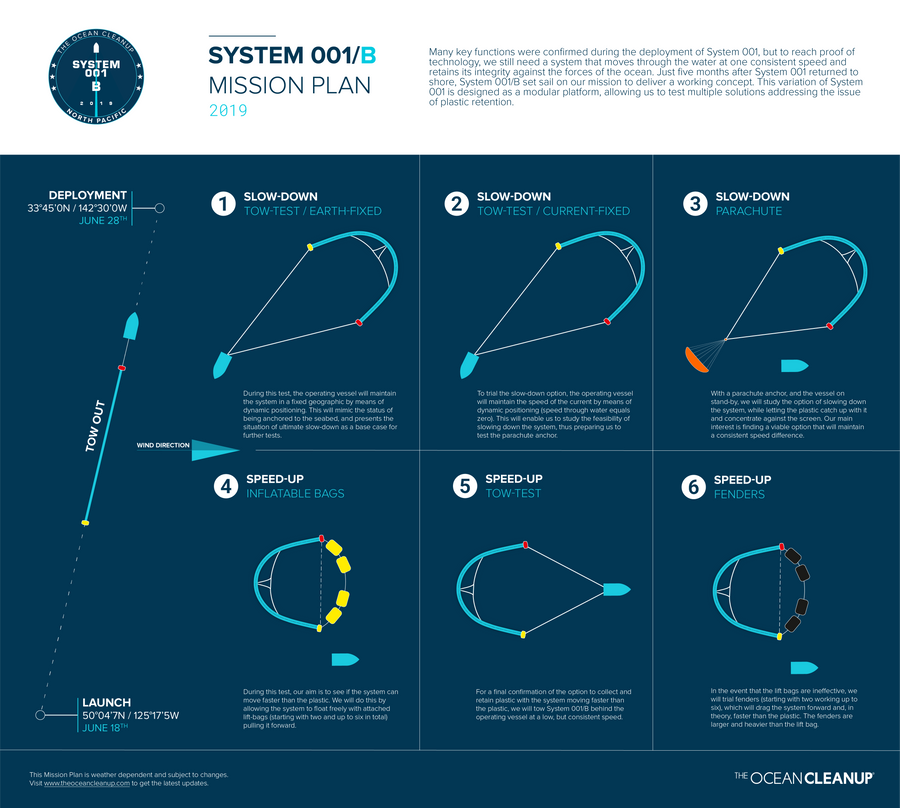

As there wasn’t a single obvious fix to this, we decided to set up the upgraded design, System 001/B, in a more modular fashion. This allowed us to trial configurations that both sped up the system and slowed it down, in an attempt to find one that would result in a consistent speed difference between the system and the plastic. We launched System 001/B in late June, which was followed by a six-week testing campaign to test slowing down the system using a parachute anchor and test speeding up the system using large inflatable buoys.

THE RESULTS

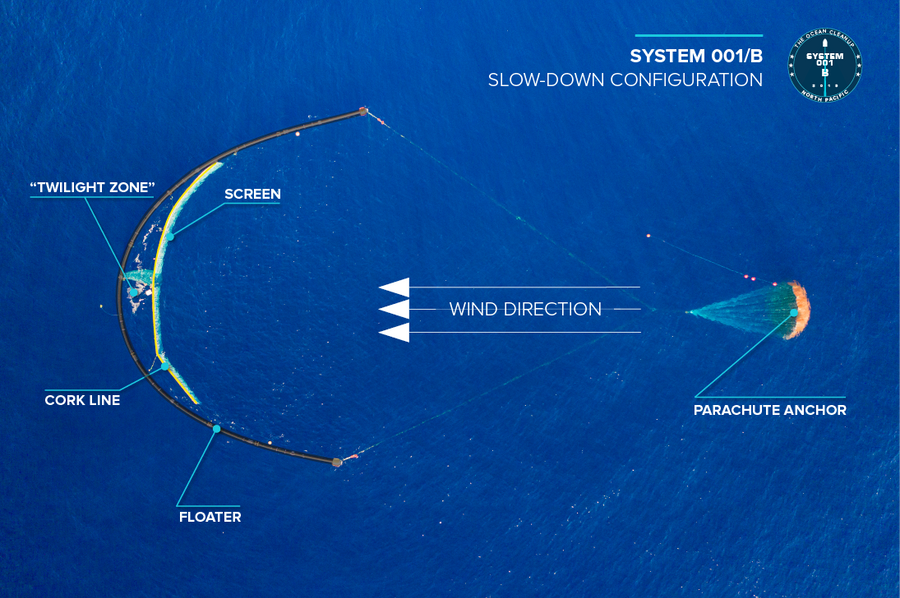

Overall, all configurations performed better than Wilson; in all tests the system generally experienced a positive speed differential, meaning that the plastic entered the system from the correct side. But the winning concept is the slow-down approach, in which we use a parachute anchor to slow down the system as much as possible, allowing the natural winds and waves to push the plastic into the system.

In the slow-down configuration, we haven’t witnessed a negative speed differential at all, with plastic always arriving through the front, but never drifting out of the opening again. Hence, this is the concept we’ll be moving forward with.

During the tests, the plastic was concentrated by System 001/B by a factor of approximately up to 10.000. If we would do this to the whole patch, we’d take the plastic distribution down from twice the size of the state of Texas, to 1/35th the size of the city of Houston; thus, proving the concentration effect.

INTO THE TWILIGHT ZONE

This is all good news and a key step in the right direction; however, we are not at proven technology status just yet. When we modified the design from System 001, we moved the screen forward slightly, away from the floater pipe, to eliminate the rail connection (cause of the fracture) and simplify the design. A cork line, like you would see to section off a swimming pool, is used to hold the screen in place and prevent it from going slack and sinking. This modification has proven mostly effective, but it creates a space between the screen and the floater, which we have dubbed: The Twilight Zone.

If you’re familiar with the popular TV series, you’ll know, there’s always a twist in each episode; well, here’s ours: the plastic is currently able to cross over the cork line into The Twilight Zone. While it is technically still within the boundaries of the system, there is no screen underneath the floater pipe, so we cannot consider this plastic caught because it is not securely retained in front of the screen.

GETTING OUT OF THE TWILIGHT ZONE

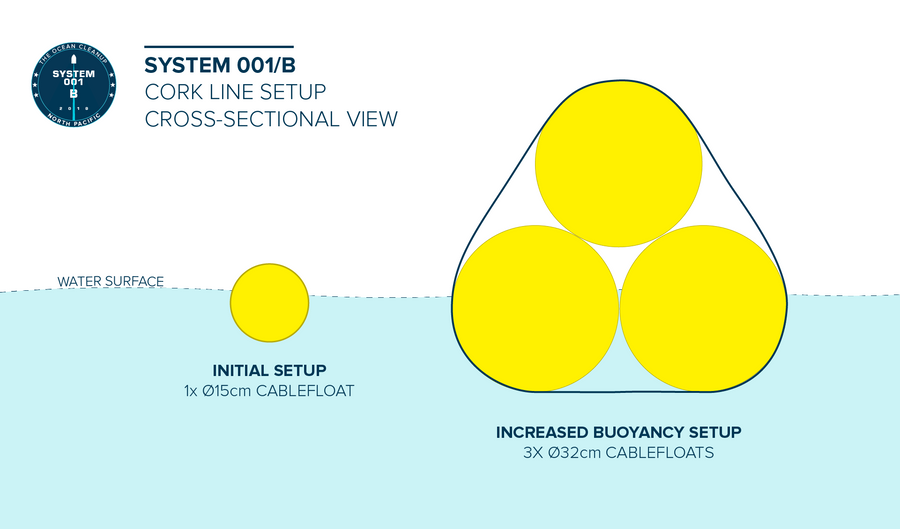

While this issue seems to be much easier to solve than the speed inconsistency issue, it is still a problem that must be solved. We will attempt to do so by massively increasing the buoyancy and height of the cork line of the screen. The floats of the current cork line measure 15 cm in diameter. In comparison, we will now be using three rows of 32 cm floats stacked on top of each other, creating a total height of about half a meter.

Production has now been completed on this modification; it is currently on its way to the patch and we expect it to arrive soon.

CLOSING

This is promising news for us, but we move forward cautiously knowing we may be presented with more unscheduled learning opportunities; overtopping might not be our only issue between now and proven technology. Yet, it is safe to say that we are closer than ever to having a tool capable of cleaning up these garbage patches for good.

As always, we will keep you updated with the results, so keep an eye out on social media.