The first Interceptor™ prototype, The Ocean Cleanup’s initial river cleanup system, was designed and built in 2017. It was deployed and tested in Zuidland, South Holland, after which adjustments were made in Capelle a/d IJssel and Batam Indonesia during the first half of 2018, before being deployed in Jakarta in 2019.

In October of 2017, the Interceptor™ prototype was designed and built in collaboration with TME, a Dutch machine-building, and engineering company. The system was then manufactured in Zwolle and subsequently installed for testing in the Spui canal Zuidland, South Holland. This location was chosen because of its high water flow velocities, which provide ideal conditions to test the robustness of the system. The system was assembled at VIS Staalbouw in Oudekerk a/d Ijssel. From there, it was shipped in two parts (pontoon and front-end) to the test location, where it was placed in the water and assembled. The original design consisted of a catamaran-shaped pontoon, on which the extracted debris is stored. The extraction equipment is situated between the floaters of the pontoon. The other components consisted of the front end, barrier, mooring, and offloading jetty.

Over the last quarter of 2017 and into the start of 2018, all components and aspects of the system, now version 1.1, were tested. Foremost, the extraction of all manner and size of debris from the water. Tests included monitoring the flow of water through the system, and thereby the route of the debris to understand where possible blockages could occur; overloading the barrier with debris to see how large amounts of debris would behave en route to the system; and the capability of the conveyor to manage the debris of various sizes and different kinds of materials. Following the extraction tests, the next phase was testing the carousel and the big-bag offloading procedure (the bags are no longer a feature of current Interceptors™), once the bags had filled up. Upon completion of the tests, adjustments were made based on the findings of our research, and we were ready to go to Asia to test in a real-river situation.

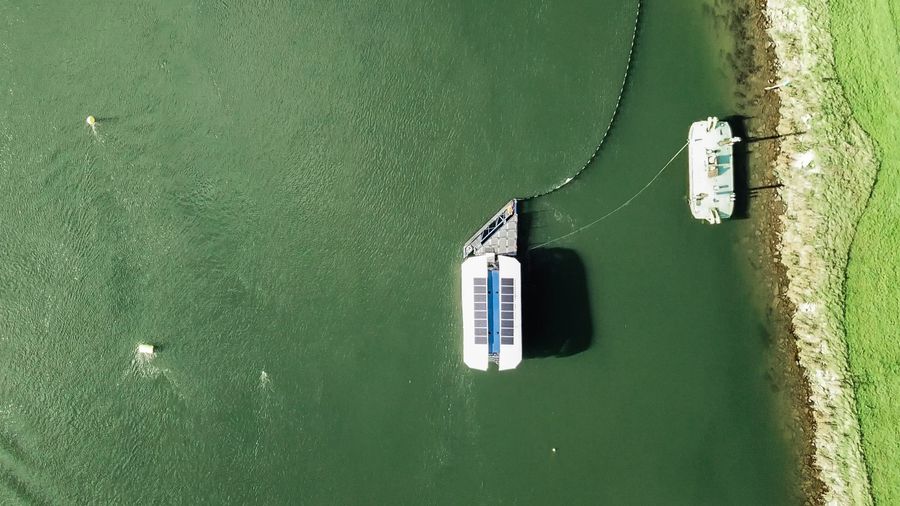

Once we had dealt with the administrative requirements and logistical arrangements, we shipped the Interceptor™ 001 to Batam, Indonesia in February of 2018. In Batam, the front-end would be assembled and some minor adjustments made. From there it would be transported to Jakarta where the assembled unit would be towed by towboat up to the Cengkareng Drain and then installed.

In February of 2019, the system was installed in the Cengkareng Drain in Jakarta, Indonesia. The system was moored to five anchor moorings that were installed on the riverbed. It was in June 2019, that the Interceptor™ was fully operational. What we learned in the first months was that storage and offloading were the biggest bottlenecks to the success of the system. The goal of the project was always to learn as much as we could from operating in a highly polluted environment. We knew that by design iteration and with the strength of our research, we could improve going forward, which is why we already we were already thinking of the design concept for Interceptor™ 2.0 at that stage.