Second North Sea Prototype to be tested in August

Back to updatesOur first cleanup system is scheduled to be deployed by mid-2018; less than 10 months from now. The Ocean Cleanup team is now moving full speed ahead towards execution, but in parallel continues to test parts of the system to maximize the chances of success.

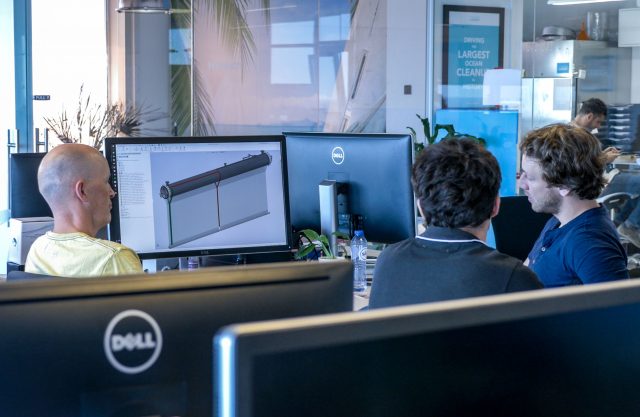

While production of the full-length floater is underway in California, the engineering team will run a new series of sub-system tests off the Dutch coast in the coming weeks. A little more than a year after the first North Sea Prototype was deployed, we return to deploy and test a segment of the cleanup system at sea, taking both the latest cleanup concept design, as well as the lessons from last year’s prototype into account.

With this second iteration of the North Sea Prototype, we will be able to test fatigue and durability performance of several sub-systems, zooming in on the screen-pipe connection. A 12-meter long pipe section will be equipped with two different screen connections; 1) wrapped around the floater and 2) connected through a rail suspension system below the floater. These tests will also let the offshore operation team practice on-site assembly procedures.

For these tests, we will make use of our North Sea test site, made available by the Government of the Netherlands. We will re-use the buoys and moorings installed for the first prototype in 2016.

The prototype is currently in production, and the floater recently passed quality control. By inflating the floater with 0.2 bar of overpressure, we were able to check for any potential leaks of the welds and components.