System 001/B – Catching the First Plastic

After completing design upgrades based on the insights from System 001, System 001/B was deployed in the Great Pacific Garbage Patch for testing as our next agile learning tool. System 001/B validated the core concept of our ocean cleanup technology and caught our first batch of ocean plastic. We later valorized this plastic into sunglasses, with the proceeds helping to fund the continuation of the cleanup.

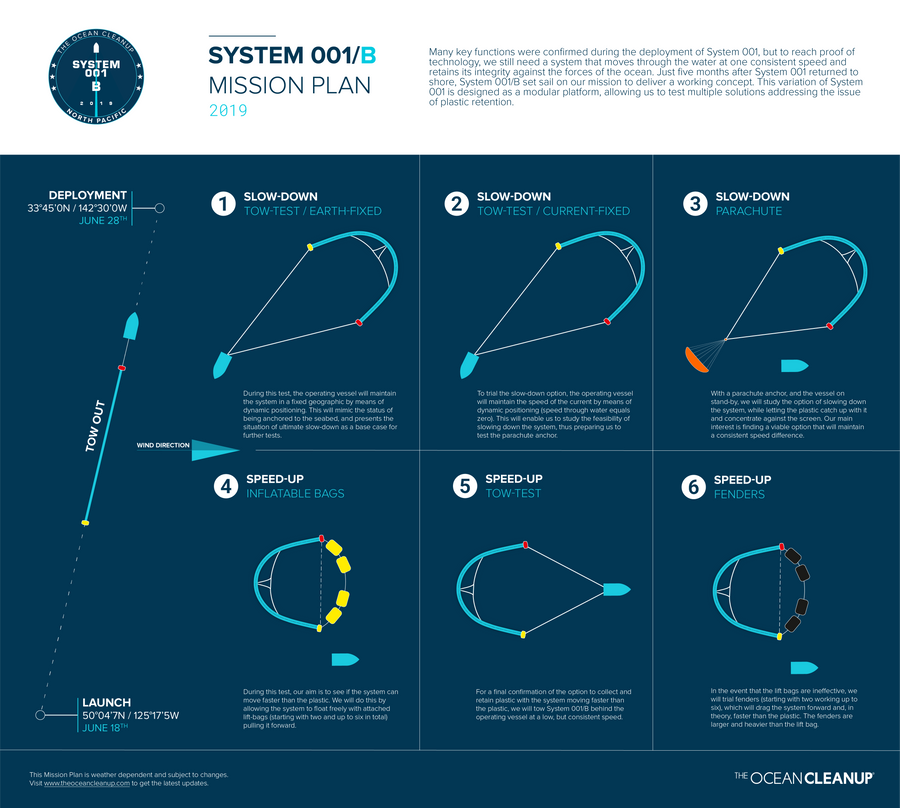

With the learnings and data collected from System 001, our engineers evolved the design platform to achieve the next iteration, System 001/B. In less than four months, System 001/B was designed, assembled, and launched. By June of 2019, it was deployed into the Great Pacific Garbage Patch for testing. Because of the system’s modularity, we were able to test multiple modifications aimed at solving the plastic retention problem observed during the System 001 campaign. Various adaptations were trialed, including: speeding up the system with buoys, slowing down the system with a parachute sea anchor, varying the underwater skirt, and adjusting the placement of the skirt to reduce the loads on the HDPE floater. This modular system could be almost entirely adapted while offshore, thus allowing us to learn as much as possible during the campaign and hastening the iteration cycles – with the eventual goal of reaching proof of concept.

It was found that the most consistent speed versus the plastic was achieved using the parachute anchor configuration, therefore solving our main technical challenge with “Wilson.” With System 001/B, we did observe the plastic overtopping the cork line that kept the new screen design afloat. To solve this issue, we installed a larger cork line that successfully prevented plastic. This resulted in preventing the plastic from crossing over this barrier and being effectively retained within the barrier. Following these last updates to the design, on October 2, 2019, we announced that System 001/B successfully captured and collected plastic debris, confirming the most important principle behind the cleanup concept first presented by Boyan Slat at a TEDx conference in 2012.

On December 12, 2019, we brought our catch onshore in Vancouver Harbour in Canada and shared our plans to transform the catch into durable products. This resulted in our first ocean plastic product – The Ocean Cleanup sunglasses. 100% of the proceeds go back into our mission and help fund the continuation of the cleanup.

Having ended this mission, our focus shifted to System 002. While the passive technology of System 001/B worked, it did not meet our scale-up ambitions, prompting a pivot in our technology strategy and the development of System 002. This next testing system will be large-scale and operational and is aimed at bringing us closer to a blueprint design for a full fleet. The design and engineering of this system will be based on the proven elements of System 001/B, namely the relative speed difference. Enhancing the efficiency will allow for faster cleanup. With System 002 we hope to gain further knowledge that will move us closer to a design validation, steps closer towards scale-up, and ultimately closer to clean oceans.