From Trash to Treasure

From the Ocean

Our first plastic catch from the Great Pacific Garbage Patch was been transformed into something useful and durable: designer sunglasses.

Own the solution

We want to give individuals all over the world the option to own a piece of plastic that once polluted the ocean, and at the same time make a valuable contribution.

Made to clean

By getting these sunglasses, supporters help us clean up 24 football fields worth of the Great Pacific Garbage Patch – and so turn the pollution of yesterday into the cleanup of tomorrow.

The plastic Journey from patch to product

The circular process of creating the new sunglasses

-

Full Circle

From Trash to TreasureWe have come full circle for the first time; catching ocean plastic and turning it into the cleanup of tomorrow. See the full journey here.

-

Catching the first plastic

The Ocean Cleanup’s first plastic was caught in the Great Pacific Garbage Patch during our System 001/B campaign in 2019. System 001/B was intended to be a test system, with components that were easily modified offshore. This allowed us to see which configuration created a sufficient relative speed difference between the system and the plastic.

-

Landing the plastic

After we completed System 001/B’s campaign, we returned to shore with the first plastic catch tagged, logged, and sealed in containers so that we can trace the plastic from the moment it leaves the ocean. Traceability is maintained throughout the Plastic Journey with the help of a third-party auditor (DNV GL), allowing us to certify that the plastic in your product actually does come from the ocean.

-

Sorting the first plastic

Once the plastic landed in the Netherlands, we could sort it by polymer type. The two main fractions of the catch have different makeups from one another – ghost nets are fibrous, while rigid plastics are hard. Because their properties vary significantly, these fractions must be recycled and processed separately. For our first product, we chose to focus on the ghost nets, because this plastic was better suited for the sunglasses.

-

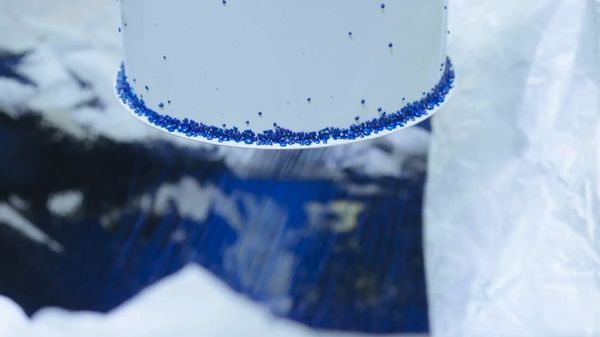

Recycling the plastic

Ghost nets require specific recycling machines for its fibrous material composition. Because ghost nets have been exposed to the forces of the ocean, recycling is more complex than would be for regular fishnets made of the same polymers. The ghost nets underwent the following recycling process: sorting, shredding, washing and drying, and extrusion.

-

Safety and regulatory compliance testing

We verified that the plastic met the regulatory requirements for sunglasses before it could undergo further processing. An independent, accredited laboratory checked for contaminants to ensure that the material meets safety standards for sunglasses. We also tested the mechanical, physical, and thermal properties of the plastic.

-

Creating The Ocean Cleanup material

Before we can mold the plastic into its new form to become a product, it will require a small, but necessary, amount of additives, such as stabilizers and pigment. These additives will allow the material to achieve the performance and technical characteristics required for manufacturing, while at the same time create a beautiful, ocean-inspired aesthetic for the product. This combination of additives is embedded in a carrier, called a masterbatch. Once developed, it has been mixed with the plastic to create The Ocean Cleanup material.

-

Processing System 001, a.k.a. Wilson

System 001, a.k.a. Wilson, our first ocean cleanup system was deployed in 2018 in the Great Pacific Garbage Patch and provided us with key insights to develop our technology further. We wanted to honor the memory of Wilson by giving it a new life in the form of the case for the sunglasses. The case has the same round shape as Wilson, and the cap mimics the look of the towheads

-

Designing the product

We strived to make a durable product and teamed up with top designer Yves Béhar and his company fuseproject to create a timeless yet iconic design, with a pattern and color palette that are reminiscent of ocean waves. We designed the sunglasses for longevity so they can be treasured for many years, but, should there come a time when they can no longer be used, they are fully recyclable.

-

Producing the product

With The Ocean Cleanup material ready, the manufacturing process could begin. Safilo, a market leader and reputable sunglasses producer, ensured that the plastic is effectively incorporated into the creation of this new, unique product that is ready for shipping and use – hereby giving the ocean plastic a second chance.

-

Unboxing

The sunglasses are packaged in a custom-designed shipping box, the Wilson case, and a pouch. The pouch resembles the look of the big bags we used to empty the cleanup system and is also made with recycled materials.

-

In your hands

The day you receive your product will be a momentous step in the plastic journey. You will have helped to clean even more plastic from the ocean by giving this plastic a new life. Wear your sunnies with pride and share a photo with #theoceancleanup and/or tag @theoceancleanup to visibly tell your story and inspire other people to join our mission. With your permission, we might even include you in a compilation video of supporters.

-

Continuing the cleanup

Every time we return to the ocean for more cleanup, it will be possible thanks to supporters like you. You can track our progress here.

OUR FIRST PLASTIC CATCH WAS MADE INTO SUNGLASSES

The first catch from our System 001/B campaign was transformed into sunglasses. Designed in California, made in Italy. They’re produced with longevity in mind, so we hope you can treasure them for many years. 100% of the proceeds will help fund our next cleanup operations in the Great Pacific Garbage Patch - creating a full circle from trash to treasure, and back again. Update: Out of stock as of February 2022.